Comprehensive data analysis for improved prediction accuracy and optimized recommendations

To increase the prediction accuracy of the model, extensive data analysis was conducted, including the evaluation of over 16,000 sensor data records from the casting process. These data were used to understand the relationship between X-ray defect features and the quality of the castings. The results of these analyses were directly incorporated into the training data for the neural network, thereby laying the foundation for the generated optimization recommendations.

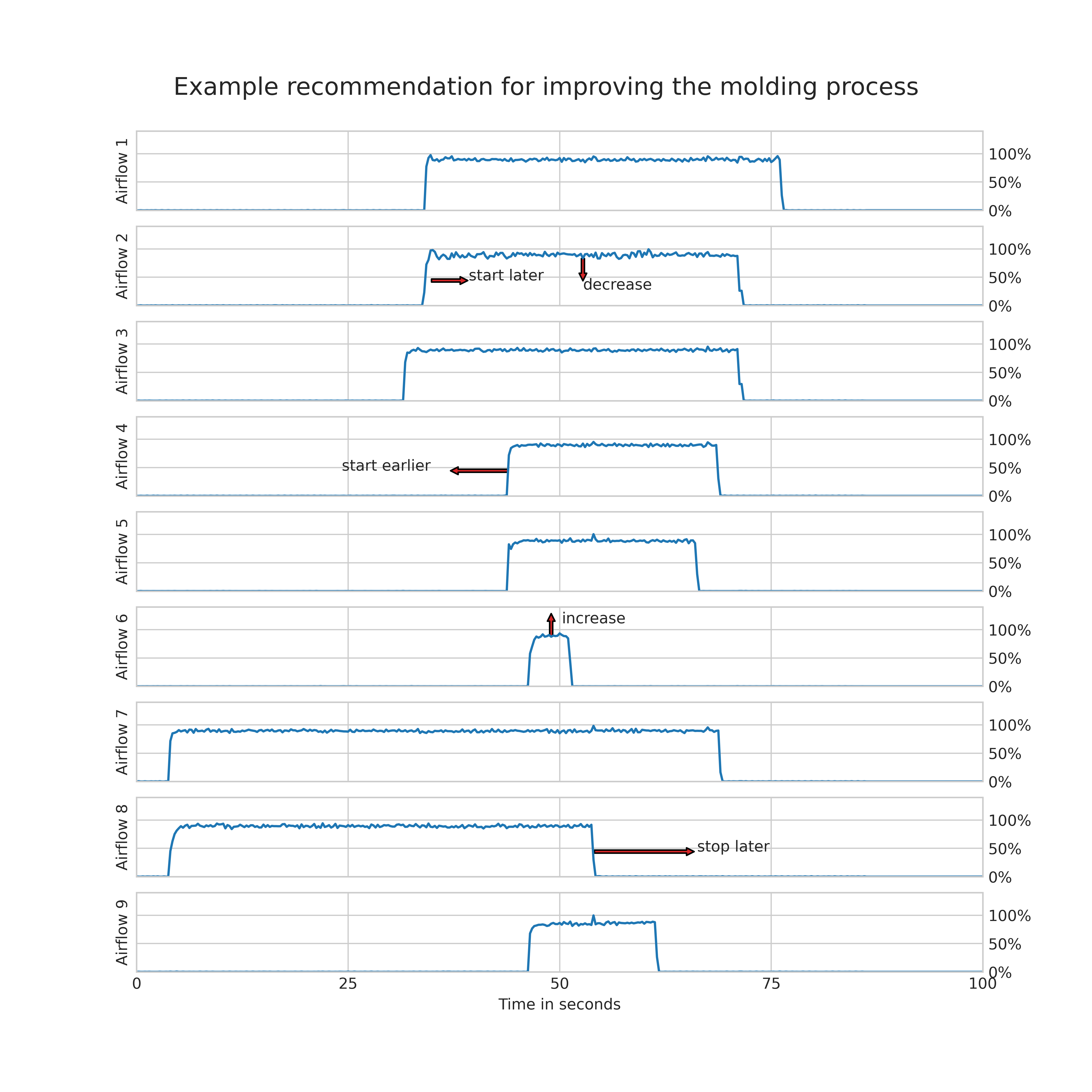

Use of »Explainable AI« for targeted adjustments

A unique aspect of the project is the use of »Explainable AI« (XAI) techniques. With XAI, it is possible to understand the decision-making process of the neural network. The influences of individual sensor data on predictions can be visualized and interpreted, allowing for targeted adjustments of production parameters. For example, XAI can show which sensor value should be increased or decreased to minimize the defect size.

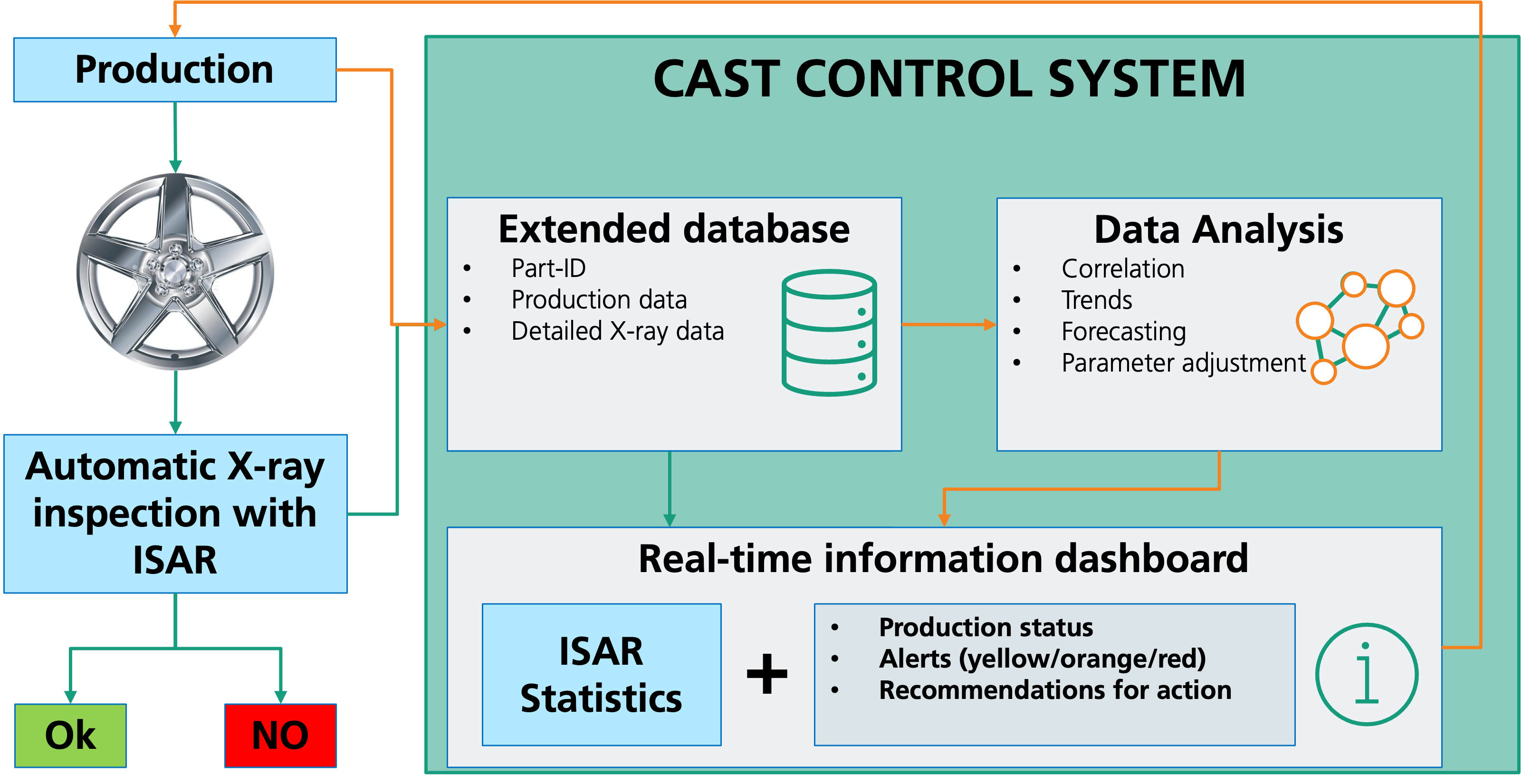

Cast Control - The next step in quality control and process optimization in production

The CastControl project takes the application of artificial intelligence to quality control and process optimization in production to a new level. In a follow-up project, the predictive reliability is now being further improved and a prototype for real-time recommendations during production is also being developed. Through collaboration with additional industry partners, the model will also be expanded to cover additional production processes. This expands the application scope and increases production quality across industries.